FITTING

Update Terakhir

04-04-2014

Dilihat Sebanyak

364 kali

Lokasi

Harga

Kontak Kami

Bagikan

+ Penawaran

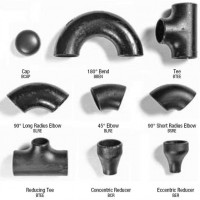

Spesifikasi FITTING

General Information about Fittings

Quality Standard for Buttweld Fittings

High quality buttweld fittings all made and controlled to the relevent standards such as: ASME, ASTM, BS and DIN/WERKSTOFFE.

Sizes for Buttweld Fittings

Buttweld Fittings are available available in sizes from 1/4” through to any size.

Wall Thickness for Buttweld Fittings

Schedule 5s through to Schedule XXS and heavier.

Dimensions for Buttweld Fittings:

- BS 1640/ANSI - ASME B16.9 - B16.28 - B16.25

- Seamless, EFW, ERW, DSAW and Forged

Material Grades for Buttweld Fittings

All buttweld fittings are available in the following material grades:

- Stainless Steel

- A403 304/L

- 310

- 316/L

- 321/H

- 347/H

- 410

- 440

- 904L

- Carbon Steel

- A234 WPB, WPC

- Low Temperature Steel

- A420 WPL6, WPL3

- Alloy Steel

- A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

- High Yield

- WPHY42, 52, 60, 65, 70

- Duplex & Super Duplex

- A815 UNS 31803, UNS 31254, UNS S32750

- UNS S32760

- Nickel Alloys

- 200, 400, K500, 600, 625, 800, 825

- Alloys

- ALLOY 20

- ALLOY C

- ALLOY C276

- ALLOY B2

- Aluminium

- 5083, 5154, 5251, 6061, 6063, 6082

- Unusual Grades

- Bronze, Brass, Copper

- Cupro Nickel

- Titanium

PT.CITRA ABADI TEKNIK INDONESIA

PT. Citra Abadi Teknik Indonesia, which is engaged in general trading, supplies pipe, fittings, bolt nut Supplier for piping construction and also as fabrication company.

We providing engineering services company and we also produces special bolt nut And flanges following the development of industry in Indonesia. Innovation is expected to be a solution and facilitators to the needs of engineering materialsfor piping, fittings and bolt nutfor strengthen your construction.

Supported by a number of staff and management who are experienced in their field, and our experienced to supplies various kind of Pipe, fittings, flanges and special bolt nut. by various high quality of machining tools, We have been able to preserve a good reputation by completing construction projects with a high standard of customer satisfaction and on time.

VISION AND MISSION

We will back up any of your specific order and your specific enquiries to field of manufacturing engineering and toproviding of services at competitive prices supported by a reliable business group to complement each other.

And support your standard construction for standard product of ANSI, JIS, DIN, MSS, AWWA, and also non-standard product flanges as your fabrication activities.

By the time, the development of technology leads to better innovation performance and continuous improvement, this is the reasons for us to always provide the best solutions and give a satisfaction to ourcustomers

We have a vision and mission to become a strategic partner capable of providing customer satisfaction and to be the best Suppliers for Pipe, Fittings, Bolt Nut and Fabrication Firm in Asia.

Kami spesialis dalam mensupport ( mensuply ) kebutuhan proyek – proyek industri seperti :

* PIPA :

Carbon steel, Galvanis ( Welded & Seamless )

API 5L, A 105 Gr. B, A 53 Gr. A/ A 53 Gr. B, Gr.X 52 Size : ½ ” – 32”

Spiral Welded Steel Line Pipe Size : ½ ” – 120”

Stainless Steel Pipe

SUS 304, 304L, 316, 316L Size : ½ ” – 24”

Alloy Steel Pipe

A333 Gr. 6, A335 P5, P11, P12

Tubing SS 316, 316L

* Fitting :

Elbow

Tee

Reducer Concentric & Eccentric

Union Coupling

Half Coupling

Hex Plug

Thredolet

Weldolet

Sokolet

Dll

Sch 10, 20, 30, 40, 60, 80, 120, 160

Class # 150, # 1000, # 2000, # 3000, # 6000

Carbon Steel :

ASTM/ ASME SA234 WPB, WPC, WPL6, A 105

Alloy steel:

ASTM/ ASME SA234 WP5, WP9, WP11, WP12, WP22, WP91

* Flange

Weld neck Flange

Slip On Flange

Blind Flange

Socket Weld Flange

Lap Joint

Class

# 150, # 300, # 600, # 900, # 1500, # 2500, JIS 10K, PN 10, 16 Dll

Matr’

ASTM A105

ASTM A182 304, 304L, 316, 316L

ASTM A350 LF 2

* Valve

Gate Valve

Glove Valve

Check Valve

Ball Valve

Butterfly Valve

Knife Gate Valve

Strayner

Type :

ANSI, JIS, PN

Matr’

A 105, A216WCB, A 350 LF2, SS 304, 304L, 316, 316L

Brand :

Kitz, Tomoe, Toyo, GLT, James Bury

BALL VALVE

Trunnion Ball Valve

* NPS 2 " ~ 36 "

* ANSI CLASS 150~ 2500

* MATERIAL: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L

* DESIGN STD: API 608, API 6D, BS 5351

* FACE TO FACE STD: ASME B16.10, API 6D

* END CONNECTION STD: ASME B16.5, ASME B16.47, ASME B16.25

* TEST STD: API 598, API 6D, BS 6755

- Carbon Steel Ball Valve :

* One-Piece Body Reduced Port Blowout-Proof Stem

* CS Trim Vented Ball

2000 PSI/ 138 Bar Non-Shock Cold Working Pressure

* MATERIAL LIST

PART SPECIFICATION

* Body : Carbon Steel ASTM A 216 Grade WCB

* Body Insert : Carbon Steel ASTM A 216 Grade WCB

* Ball ( Vented) : CF8M Stainless Steel ASTM A 276 Type 304 or ASTM A 351 Type CF8M

* Stem: Carbon Steel ASTM A 108 Type 1018

* Seat : Reinforced TFE

* Thrust Washer : Reinforced TFE ( Carbon 25% Teflon 75% )

* 1Stem Packing: Graphoil

* Threaded Pack Gland : Carbon Steel ASTM A 108 Type 1045

* Handle Nut : Carbon Steel ASTM A 283

* 2Handle: Carbon Steel ASTM A 283

Class 150~ 1500 Cast Steel Fixed Ball Valve

* Bolted cover, Two-piece or three-piece Body, fixed Ball

- Full or Reduced bore, Blowout Proof Stem

* Fire safe and Anti static

* Dual seat with injection and drain & outlet

* ASTM A216 WCB, A351 CF8, A351 CF8M,

* A351 CF3, A351 CF3M, A351 CN7M

Standards compliance

* Design and Manufacture: API 6D

* Face to face( end to end) : API 6D

* Flanged connection: 2~ ~ 24~ to ANSI B16.5

* Fire-safe: API 607, API 6FA

* Butt welded end: ANSI B16.25

* Test and inspection: API 6D

- ECCENTRIC SEMI BALL VALVE

Detailed Product De

* Nominal pressure: PN6, PN10, PN16, PN25 and PN40

* Nominal dimensions: DN50~ DN1000

* Material: ductile cast iron GGG50, WCB, A105, 304, 316 ( body) , 304, 316 ( ball)

* Suitable medium: water, steam, oil

* Suitable temperature: soft seal below 150-degree, metal-to-metal * seal below 420-degree

* Design and manufacturing standard: DIN, AMSE and API

* Driving: manual, worm gear, pneumatic and electric

* Connecting: flange

- ELECTRIC BALL VALVE

Features:

* Product: HL electric ball valve 1

* Adopted power: AC 110V, 220V, 380V, DC 24V

* Input signal: 4 - 20mA, 0 - 10mA or 1 - 5V DC

* Valve material: stainless iron

- FEMALE BALL VALVE :

Specifications:

* Brass body

* Nickel plated

* Iron or stainless steel handle

* Size: ½ " -2 "

- FLANGED BALL VALVE

* 2-PC FLANGED / HOSE BALL VALVE

FULL PORT

* INVESTMENT CASTING

ISO 5211 DIRECT MOUNTING PAD

* BLOWOUT PROOF STEM

ANTI-STATIC DESIGN

* AVAILABLE MATERIAL: 1.4408 / 1.4308

* FLANGE DIMENSION: DIN2633 / EN1092-1

* FACE TO FACE: DIN3202 / EN558-1 F1 / F4

* FWORKING PRESSURE: PN 40 / 16

WORKING TEMPERATURE: -20° F---400° F ( -29° C- 200° C)

* AVAILABLE SIZE: DN15---DN100

- FLOATING BALL VAVE :

CLASS 150~ 300 FLOATING BALL VALVE

* Bolted bonnet, Two-piece

* Body, Floating Ball

* Full or Reduced bore, Blowout Proof Stem

* Fire safe and Anti static

Stainless steel ball

* ASTM A216 WCB, A351 CF8, A351 CF8M,

A351 CF3, A351 CF3M, A351 CN7M

Standards compliance

* Design and Manufacture: API 608, API 6D, BS5351

* Face to face( end to end) : ANSI B16.10, API 6D

* Flanged connection: 2~ ~ 24~ to ANSI B16.5

* Fire-safe: API 607, API 6FA

* Butt welded end: ANSI B16.25

* Test and inspection: API 598, API 6D

FORGED STEEL BALL VALVE :

Detail Product De

1) Design standard: API6D, API600, ANSI B16.34, BS 5351, DIN3202

2) Face to face: API6D, API594, ANSI B16.10, DIN3202

3) Flanged ends: ANSI B16.5a

4) Test & inspection: API 6D & API 598

5) Main Material:

Carbon Steel: WCB, A105

Size: 1/ 2' ~ 36' Pressure: 150LB~ 2500LB

Alloy Steel: CrMo, 20CrMo, 25CrMo, WC1, WC6, WC9

Size: 1/ 2' ~ 24' Pressure: 150LB~ 2500LB

Low temperature steel: LCA, LCB, LCC, CF1, CF2, CF3

Size: 1/ 2' ~ 16' Pressure: 150LB~ 600LB

Stainless Steel: CF8, CF8M, CF3, CF3M, 304, 316, 304L, 316L, 321

Size: 1/ 2' ~ 36' Pressure: 150LB~ 2500LB

PIPA

PIPA

Carbon Steel , Galvanis ( Welded & Seamless) Api 5L, A106Gr.B, A 53 Gr.A & B, Gr.X, X52 Dia.1/ 2’ ’ – 36’ ’ Dll

Spiral Welded Steel Line Pipe Dia.4’ ’ – 36’ ’ , Stainless Steel Pipe, Alloy Steel Pipe A33 Gr.6/ A335 P5, P11, P12, Tubing SS316/ 316L Dll

Ex . Japan, China, Korea, Spain

GATE VALVE

ANSI GATE VALVEProduct De

1. Design and manufaturing per API 600

2. Face to face dimensions per ANSI B16.10

3. Flanged connection per ANSIB16.5

4. Test and inspection per API598, API600

5. Body material: WCB CF8 CF8M CF3 CF3M WC9 C5

CLASS 150~ 600Lb BELLOWS GATE VALVE :

* OS& Y, Rising stem, Bolted lengthen bonnet, welded seat ring, full bore stainless trim

* ASTM A216 WCB

* A357 LCB LC1 CL2 LC4

* A351 CF8 CF8M CF3 CF3M

* A217 WC1 WC6 WC9 C5 C12

CAST STEEL GATE VALVE :

OS& Y, Rising stem, Flexible Wedge

Bolted Bonnet, Threaded or welded seat ring

ASTM A216 WCB, A217 WC6, A351 CF8, A351 CF8M,

A351 CF3, A351 CF3M, A351 CN7M

Standards compliance

* Design and Manufacture: ANSIB16.34, API600 API6D, API603, BS1414

* Face to face( end to end) : ANSIB16.10, API6D

* Flanged connection: 2 " ~ 24 " to ANSIB16.5, 22 " , 26 " ~ 36 " to MSS-SP-44 to API605 on Request

* Test and inspection: API598, API6D

Butt welded end: ANSIB16.5

A. Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

B. Grub screw: Secures yoke nut in the bonnet

C. Grease nipple: Supplies lubricant to the mating parts

FORGED STEEL GATE VALVE :

Applied Standard

1. Design and Manufacture: According to Standard: ANSI, B16.34, API, 602.

2. Size of the Junction End:

( 1) The size of bell and spigot hole is designed according to standard: ANSI, B16.11, JIS, B2306.

( 2) The size of the threaded end is designed according to standard ANSI1 B1.20.1 B21 ISO7/ 1 JIS B0203.

3. Testing of Valves: According to API 598.

4. Structure Characteristics: B.B; OS& Y or W.B; OS& Y.

5. Materials: According to the requirements of AISI/ ASTM.

6. Main Materials A105; F5; F11; F22; 304; 304L; 316; 316L; Lf2 etc.

KNIFE GATE VALVE :

Features:

1. Standard: API, DIN

2. Size Range: 2 " -28 "

3. Pressure: 150Lb-300Lb

4. Other features:

a) Handwheel torque or actuator force provides positive seat- knife closure

b) During closure, the stem slides down pushing the knife into contact with the two bottom lugs

c) The taper stem head then transfers a vertical closing force to a lateral force which positively seats the knife against the seat face

d) Stem force, not line pressure, maintains seating contact in this unique design, ensuring tight seating in both directions

e) During the opening and closing cycle, the guides ensure proper alignment of the knife

FLANGE GATE VALVE :

* Design by API Spec.6D and API 600

Valves tested by API Spec. 6D and API 598

* Face to Face by API Spec.6D and ANSI B16.10

* RF flanged ends by ANSI B16.5 and MSS SP-44

* Butt-Welding ends by ASME B16.25

Material Origin : Ex. Japan, Eropa, USA, China, Korea

CHECK VALVE

API CHECK VALVE :

1) Bolted cover

2) Flanged or butt-welded ends

3) Standards compliance

4) Design and manufacture: API 6D, BS1868, ASME B16.10

5) Face-to-face dimension: API 6D

6) End flange: ASME B16.5

7) Inspection and test: API 598, API 6D

8) NPS: 2 " -48 "

9) Pressure: class 150lbs-2, 500lbs

10) Material: WCB, WCC, LCB, LCC, WC6, WC9, C5, C12, CF8, CF8M, CF3, CF8C, CN7

CAST STEEL SWING CHECK VALVE :

Features:

1) Class 150~ 1500 swing check valve

2) Bolted cover, swing type disc

3) Threaded or welded seat ring

4) Standards compliance

a) Design and manufacture: ANSIB16.34, API6D, BS11868

b) Face to face ( end to end) : ANSIB16.10, API6D

c) Flanged connection: ANSI B16.5

i) 2 " ~ 24 " to ANSIB16.5

ii) 22 " , 26 " ~ 36 " to MSS-SP-44

iii) To API605 on request

d) Test and inspection: API598, API6D

e) Butt welded end: ANSI B16.25

FORGED STEEL LIFT CHECK VALVE :

1.Design and manufacture conform to: API, ANSI, JIS, DIN, JB.

2.Test and inspection conform to: API598, GB/ T13927, JB/ T9092

3.Pressure: from ANSI class 150 to 2500 ( PN1.6 - 42MPa)

4.Structure features: Bolted bonnet, welted bonnet, pressure seal bonnet

5.Connection ends conform to:

Butt-welded ends dimension conform to ANSI B16.11; JB/ T1751

Flanged ends conform to ANSI B16.5; JB79

Screw ends dimension conform to ANSI B1.20.1; JB/ T7306

Socket welded ends dimension conform to ANSI B16.11; JB/ T1751

6.Materials conform to ANIS/ ASTM

7.Main materials: A105; LF2; F5; F11; F22; 304( L) ; 316( L) ; F304( L) ; F316( L) ; F347; F321; F91; Monel; 20Alloy

SWING CHECK VALVE :

CLASS 150~ 1500 SWING CHECK VALVE

Bolted cover, swing type disc

Threaded or welded seat ring

ASTM A216 WCB, A217 WC6, A351CF8, A351CF8M, A351 CF3, A351 CF3M, A351 CN7M

Standards compliance

Design and Manufacture: ANSIB16.34, API6D, BS11868

Face to face( end to end) : ANSIB16.10, API6D

Flanged connection: 2~ ~ 24~ to ANSIB16.5

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ 22~ , 26~ ~ 36~ to MSS-SP-44

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ to API605 on request

Butt welded end: ANSIB16.25

Test and inspection: API598, API6D

WAFER CHECK VALVE :

Wafer Check Valve

NPS 1/ 2 " ~ 20 "

ANSI CLASS 150~ 300

MATERIAL: WCB, CF8, CF8M, CF3, CF3M

DESIGN STD: ANSI B16.34

END CONNECTION STD: ASME B16.11, ASME B1.20.1, ASME B16.25

TEST STD: API 598

Material Origin : Ex. USA, Japan, Eropa, Korea, China.

ELBOW

ELBOW

SIZE :

1/ 2 " - 48 "

RATING :

SCH 10, 20, STD, 40, 60, 80, 120, 160, 150# , 3000#

Material :

ASTM/ ASME SA234 WPB, WPC, WPL6

ASTM/ ASME SA234 WP5, WP9, WP11, WP12, A 105, SUS 304/ 304L, SUS 316/ 316L

TEE, RED TEE, CROSS TEE

TEE, RED TEE, CROSS TEE

SIZE :

1/ 2 " - 48 "

SCH : 10 " , 20, STD, 40, 60, 80, 120, 160

CLASS : 150# , 3000#

MATR' :

ASTM/ ASME SA234 WPB, WPC, WPL6, ASTM/ ASME SA234 WP5, WP9, WP11, WP12, WP22, SUS 304/ 304L, 316/ 316L

MATR' ORIGIN :

JAPAN, EROPA, USA, TAIWAN, CHINA, THAILAND

REDUCER CONCENTRIC, REDUCER ECCENTRIC

REDUCER CONCENTRIC, REDUCER ECCENTRIC

SCH : 10 " , 20, STD, 40, 60, 80, 120, 160

CLASS : 150# , 3000#

MATR' :

ASTM/ ASME SA234 WPB, WPC, WPL6, ASTM/ ASME SA234 WP5, WP9, WP11, WP12, WP22, SUS 304/ 304L, 316/ 316L

MATR' ORIGIN :

JAPAN, EROPA, USA, TAIWAN, CHINA, THAILAND

FORGED STEEL ELBOW

Forged Steel Socket Weld/ Threaded Elbow

Elbow 90Degree/ 45Degree

1/ 2 " to 4 " class 2000 threaded

1/ 2 " to 4 " class 3000 threaded & socket weld

1/ 2 " to 4 " class 6000 threaded & socket weld

1/ 2 " to 2 " class 9000 socket weld

Material :

A 105, ASTM A 182 F304/ 304L, ASTM A182 F 316/ 316L

Origin :

Taiwan, China, Japan, Eropa, USA

Forged Steel Socket Weld/ Threaded Fittings

Forged Steel Socket Weld/ Threaded Fittings

Tee

1/ 2 " to 4 " class 2000 threaded

1/ 2 " to 4 " class 3000 threaded & socket weld

1/ 2 " to 4 " class 6000 threaded & socket weld

1/ 2 " to 2 " class 9000 socket weld

Material :

ASTM A105, ASTM A182 F304/ 304L, ASTM A316/ 316L

Origin :

Taiwan, China, Korea, Japan, Eopa, USA

BUTTERFY VALVE

CAST STEEL BUTTERFY VALVE :

Features:

1) Sizes: 100mm - 800mm

2) Seal: stainless steel / fluorine plastic

3) Body: cast steel

4) Disc: cast steel

5) Stem: stainless steel

6) Standard: JB, GB/ T, DIN

7) Type: two-way cast steel butterfly valve

8) Pressure: 1.6MPa ( 16kg)

9) Connection type: flange end

10) Control method: gear driven

11) Advantages: good appearance, long service life and flexible switch

LUG BUTTERFLY VALVE :

Lug Butterfly Valve, We are one professional Lug Butterfly Valve, Lug Butterfly Valves Manufacturer and Lug Butterfly Valve Export in China.We can produce Butterfly valve, Lug Butterfly Valve, Lug Valve according to your requirements. If you are interested in any of Butterfly valves or Lug Butterfly Valves or have a customized requirement to fill, please contact us right now !

Product De

Lug Butterfly Valve

Size: NPS 2 " -72 "

Pressure: Class150 - 3000

Material: WCB, WC1, WC5, WC6, WC9, WC12, CF3, CF8, CF3M, CF8M410, 304, 316, 304L, , 38CrMoAlA, 25Cr1MoV

Design & Manufacture Std.: BSBS 5155, API 609, MSS SP-67, and MSS SP-68

Face to Face Std.: BS 5155, and API 609, MS

End Connection Std.: ASME B16.5, and DIN2543-2545

Test Standard: ISO5208, and BS 6755

Structure Type: Center line pattern, double eccentric pattern, three eccentric pattens

Operated Way: Lever, gear, pneumatic, and electric

Standard : API, JIS, DIN, BS, GB

FLANGED BUTTERFLY VALVE :

Test and inspection: API598End connection: WaferBody: CI, DI, Carbon Steel, Stainless SteelDis: DI, Al-bronze, Stainless steel, Carbon SteelSeat: EPDM, NBR, PTFE, Shaft: Stainless steel, Carbon steelControl Actuator: Handles, gear, electric and pneumaticTemperature Range: -10-176° C PN.1.0Mpa 1.6MpaMedium: water, Oil, Gas Packing: Wooden with carton inside

Pneumatic Eccentric Butterfly Valve

pneumatic eccentric butterfly valve:

It has unique eccentric configuration. It is of compact configuration, good bellows seal and long performance life, and has two functions of both the regulating and shut-off valves. It is widely applied to chemical plant, paper making, electric power, spinning mill, pharmacy, packinghouse and sewage farm under regulating and controlling systems

Main technical parameters:

1) Nominal size: DN 50-600mm

2) Nominal pressure: ANSI 150-600lbs

3) Flange standards: ANSI

4) Leakage class: ANSI IV/ V/ VI

5) Body' s material: WCB/ CF8/ CF8M

Characteristics:

1) Equal percentage

2) Temperature range: -60~ + 450° C

WAFER BUTTERFLY VALVE :

Product De

Size: NPS 2 " - 72 "

Pressure: Class150 -1500

Material: WCB, WC1, WC5, WC6, WC9, WC12, CF3, CF8, CF3M, CF8M410, 304, 316, 304L, , 38CrMoAlA, 25Cr1MoV

Design & Manufacture Std.: BS 5155, API 609, MSS SP-67, MSS SP-68

Face to Face Std.: BS 5155, API 609, MSS SP-67, MSS SP-68

End Connection Std.: ASME B16.5, DIN2543-2545

Test Standard: ISO5208, BS 6755

Structure Type: Wafer, flanged

Operated Way: Worm gear, pneumatic, etc.

Material Origin : Ex. USA, Japan, Eropa, Korea, Taiwan, Jerman , China.

Free Member

Head Office : JL.CELEBRATION BOULEVARD BLOK AA5 NO.09 GRAND WISATA TAMBUN SELATAN - BEKASI Workshop : JL.AMD No.57 Ds.Cileduk Kec.Setu - BEKASI

Login Terakhir 30-05-2015

62-21-82615670

Produk Lainnya