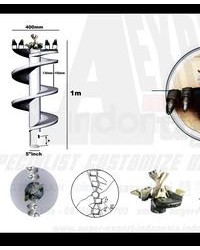

Mata Bor Diamond Impregnated Asahi

Spesifikasi Mata Bor Diamond Impregnated Asahi

The broad objective of a diamond impregnated drill bit is to produce a bit where the matrix under given conditions, erodes at a rate so that. as the active diamonds become blunt they will be released and a fresh sharp diamond will be exposed to continue cutting. The matrix is a critical factor in impregnated bit manufacture as it must have the capacity to retain the diamonds for as long as they continue to cut and then allow the blunt diamonds to “strip” but resist the drilling forces and not allow the sharp diamonds to be “pulled” prior to becoming blunt.

Diamond concentration is also critical to an impregnated bits performance as it is believed that the increase in concentration increases “strip rate” and also increases the load required for “self sharpening”. There are two elements of an impregnated bits matrix, one is the matrix is far to hard and will not allow worn diamonds to “strip” and the other where the matrix is to soft and allows premature release of the diamond before they are at the end of their useful life.

Our bits are commonly used throughout the drilling industry to perform goetechnical, gas drainage, gas content coring, material sample coring and mineral exploration

Asahi Diamond Industrial Indonesia

The first year of taking over period in 2003 the company has shown the remarkable revenue achievement which was 80% increase from the prior year 2002. This effected to the company profit increase of 77% compared to the prior year 2002.

In the middle of 2005 the company decided to expand its market by getting approval of the expansion permit from Indonesia Investment Coordinating Board No. 302/II/PMA/2005 Dated October 11th 2005 in the end of that year. The purpose of the company expansion was to vary another product called Drill Rod and Casing and Drill Equipment which showed high requirement in market demand. This opportunity was taken by the company and was supported by the holding company which was signed by the agreement of paid up capital and long term loan with the very competitive interest rate.

The first production process for new product commenced in July 2006 and the demand of this kind of product has increased significantly. Within first 6 (six) month period the sales of new product has made a satisfactory contribution to the whole sales during the period in 2006 which was 24% of total sales and enhanced the revenue record of 70% increase in 2006 compared with the prior year.

The company has realized that to maintain a good performance needs professional human resources and very competitive material prices. These two sides has become the